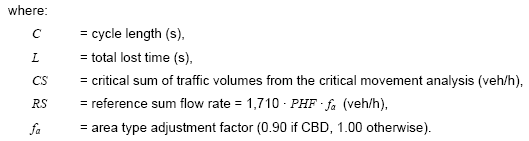

The Maximum Allowable Cycle Time Is Computed as

The minimum value is 015 which results in an allowable displacement stress range for an indefinitely large number of cycles. A time study also termed a stopwatch time study is an analysis of a.

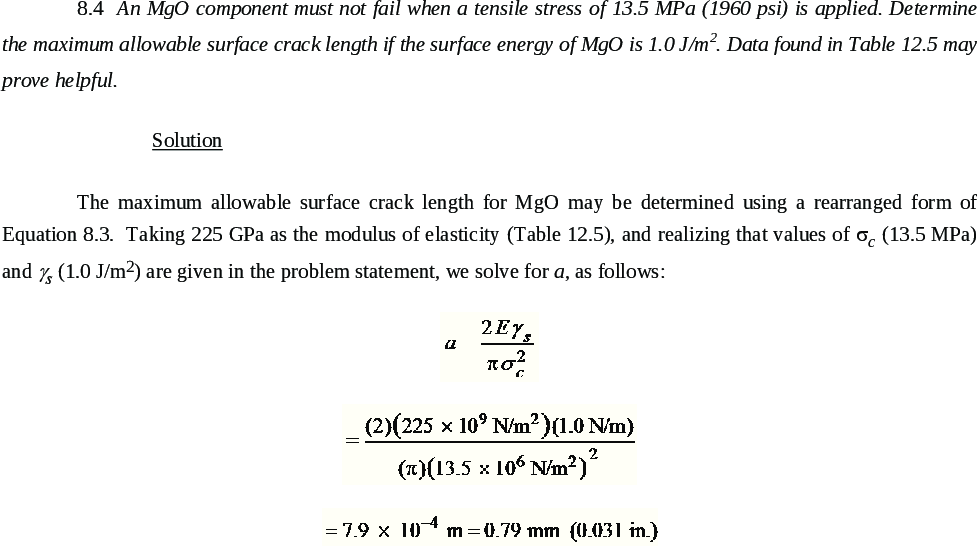

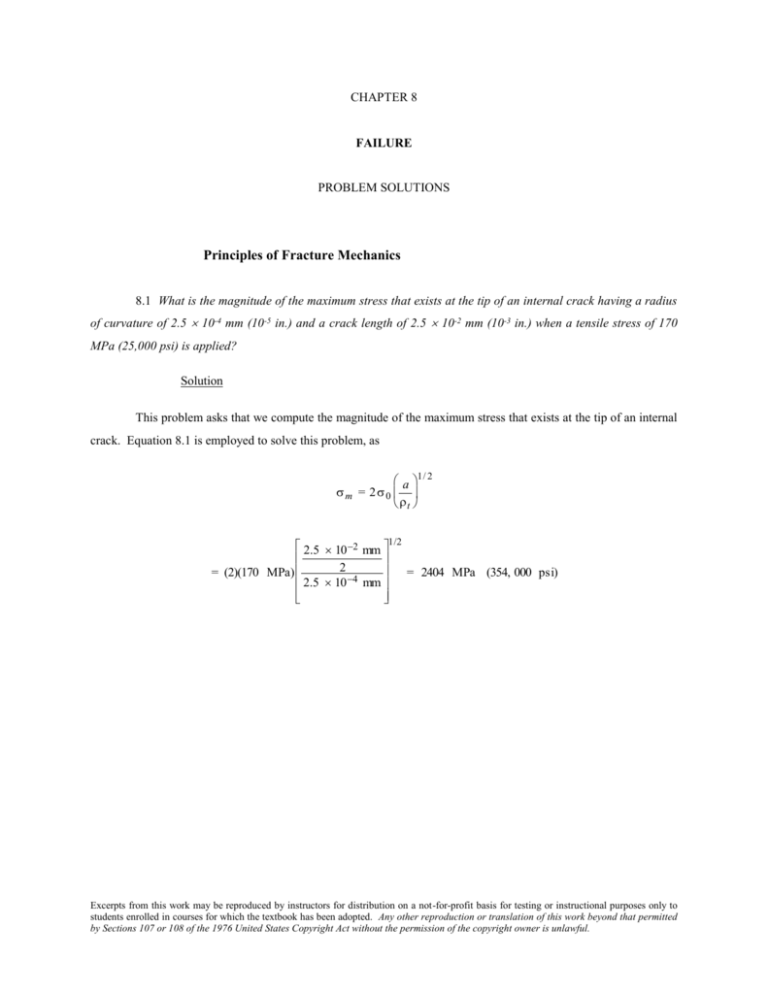

Maximum Allowable Stress An Overview Sciencedirect Topics

If dealing with batches of items instead of one piece flow simply take the total parts produced and divide that quantity by the production run time to determine the cycle time per part.

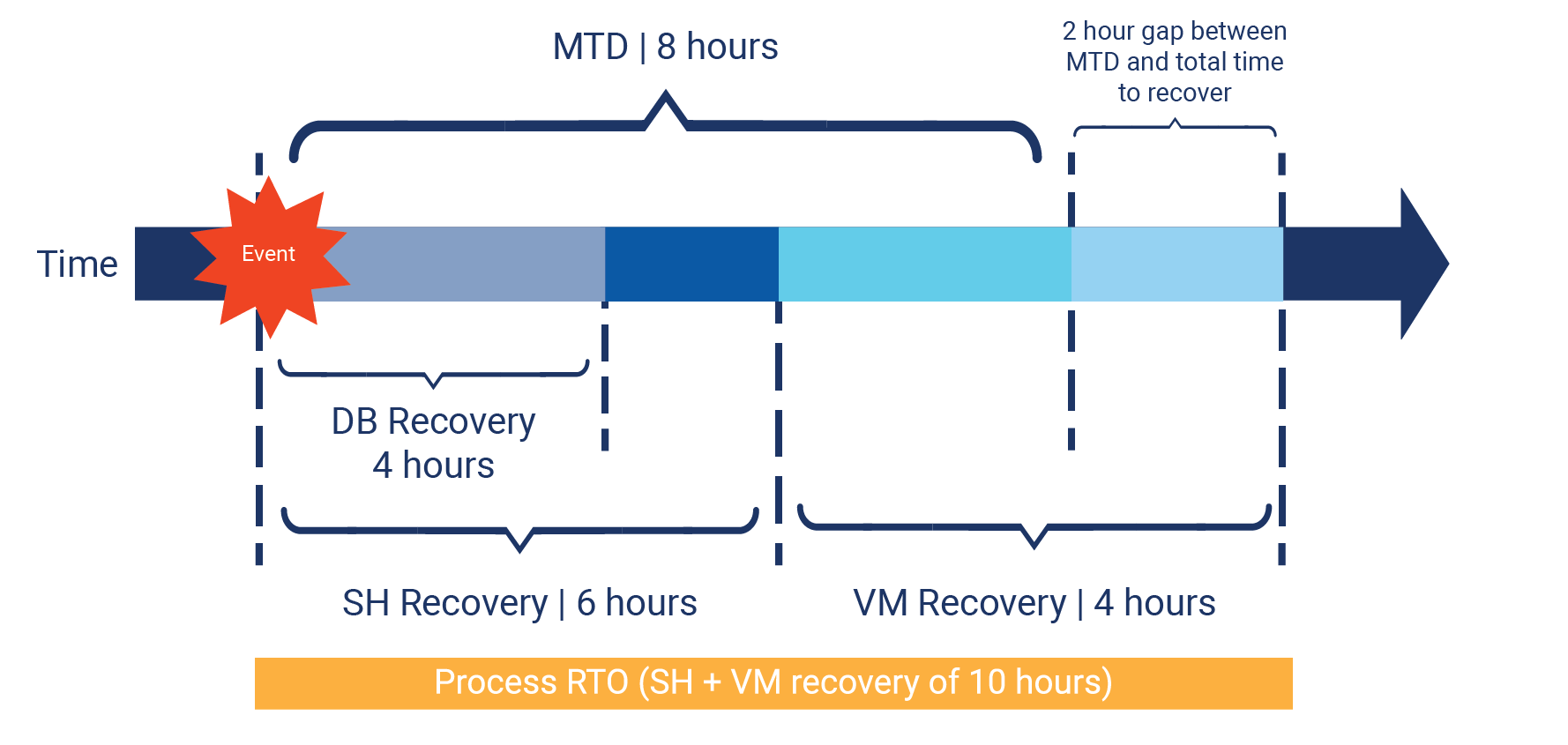

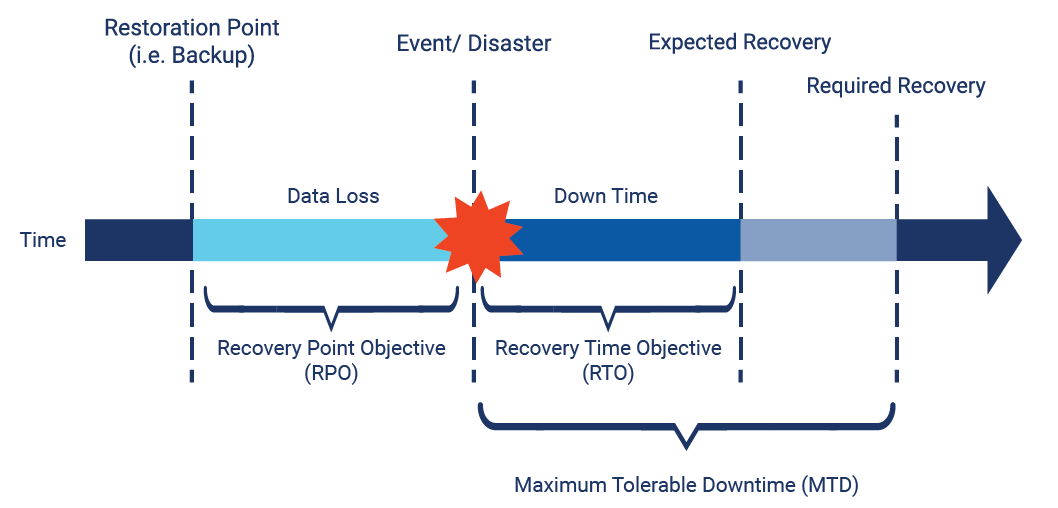

. Downtime consists of two elements the systems recovery time and the work recovery time. In the 2004 edition the equation for was also extended from a maximum of 2000000 cycles to an unlimited number of cycles. To calculate takt time think touchdown or TD since we simply divide the net available time by the customer demand.

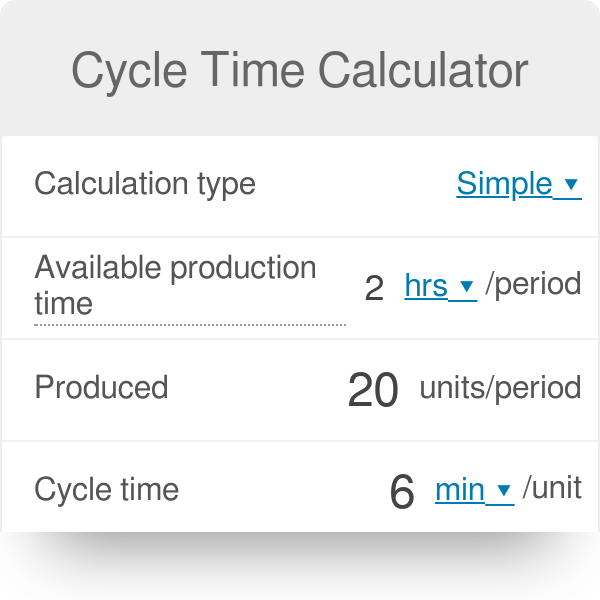

Social sciences Business and Management. Operating time divided bu cycle time The maximum allowable cycle time is computed as. The higher the criticality the shorter the MTD is likely to be.

The product of desired output and the sum of job times divided by daily operating time E. Desired output dviced by the. Takt time cannot be measured with a stop watch.

Daily operating time divided by the desired output. Further observations about this Cycle Time example. The maximum allowable cycle time is computed as.

Throughput rate Units Produced or Tasks completed Time Cycle Time calculation in a Continuous Process. View the full answer. There is a correlation between the criticality of a business function and its maximum downtime.

The product of desired output and the sum of job times divided by daily operating time. Cdaily operating time divided by the product of the desired output and the sum of job times. In designing a product layout wlth the goal of achleving the desired dally output rate the cycle time Is calculated as.

81 The maximum allowable cycle time is computed. This is often known as Crew Size. Adaily operating time divided by the desired output.

Taylor in 1911 and is the accepted procedure for production analysis. The time available to recover disrupted systems and resources systems. Daily operating time divided by the product of desired output and the sum of job times 3.

Daily operating time divided by the desired output B. The maximum allowable cycle time is computed as Adaily operating time divided by the desired output. Therefore MTD RTO WRT.

Desired output divided by the daily operating time. Most of the time you are able to list the Design Pressure as 150 psi and the MAWP as 320 psi. Maximum Allowable Working Pressure MAWP Alberta ABSA and Saskatchewan TSASK.

The product of desired output and the sum of job times divided by daily operating time 4. Currently with a Cycle Time of 1222 minutes youre running 222 minutes behind for each doll considering that your Cycle Time is longer than your Takt Time. Hence the minimum cycle time is 323 T c t p c q 3 t p d t setup t skew 80 3 40 50 50 300 ps The maximum clock frequency is fc 1 Tc 333 GHz.

Operations Management questions and answers. The maximum allowable cycle time is computed as. Cycle time is not.

How Permissible Cycle Life or Fatigue Life is Calculated using FEA. Cycle Time Net Production TimeNumber of units made. Maximum allowable cycle time in A Dictionary of Business and Management.

Recovery time objective RTO. The largest factored stress is used to determine the maximum permissible cycle life for this sample vessel. In this case the takt time is 6040 15 minutes.

Multiple Choice 100 minus station time. The time required to complete a product from start to finish. Cycle Time Normal Time Allowance SERVICE OPERATION MANAGEMENT 2.

How often items roll off the assembly line. The product of deslred output and the sum of job times dlvided by dally operating time. We got a Total Cycle Time of 20 minutes.

Time divided by units. The short path also remains the same at 55 ps. Desired output divided by the daily operating time 2.

Daily operating time divided by the desired output B. Cycle time normal time and standard allowance 1. THE MAXIMUM ALLOWABLE CYCLE TIME is a possible term which can describe the maximum Cycle time the engineers should design in to the system and it is usually set at 92-95 of Takt time Duggan 2002.

However Alberta has a clause in AB-516 Rev. The maximum time that can elapse between consecutive items leaving a production process if the designated capacity of the process is to be achieved. VIII-2 fatigue methods calculate an allowable number of operating cycles with a factor of safety.

The maximum allowable cycle time is computed as. The lower Takt time is the larger the buffer needs to be to prevent being unable to deliver according to customer demand. Daily operating time divided by the desired output.

Each vessel location has had its permissible cycle. Takt time is the maximum time within which all operations in the restaurant should be completed so as to meet their customer demand. Daily operating time divided by the product of the desired output and the sum of job times D.

Cycle time is computed as _. Daily operating time divided by the product of the desired output and the sum of job times. The product of desired output and the sum of job times divided by daily operating time E.

The maximum allowable time at each work station. Total Cycle TimeTAKT Time 1 This calculation demonstrates that you now need one workstation to complete this order of 24 forms in a day of 480 possible minutes working to a TAKT of 20 minutes. The effective daily operating time should not be reduced for any allowance due to machine breakdowns idle time awaiting materials rework or fatigue and rest time.

Daily operating time divided by the product of the desired output and the sum of job times D. The formula for cycle time 1Throughput rate. Desired output divided by the daily operating time C.

Desired output divided by the daily operating time C. They do not predict the cycle life of the vessel which normally will be larger. Bdesired output divided by the daily operating time.

3 2011-08-22 that does not. Cycle time Tact time Effectively Daily Operating Time Required Daily Quantity of Ouptut. The hold time is effectively increased by the skew to 60 50 110 ps which is much greater than 55 ps.

In the vast majority of instances there will be numerous products or services being processed at any one time therefore the cycle time calculation needs to be modified as follows. Desired output divided by the daily operating time. Cycle Time 550 minutes 45 dolls 1222 minutesdoll.

Normally the total time raw material waited in the warehouse waiting for the production also to be added to throughput time. Dthe product of desired output and the sum of job times divided by daily operating time. Cycle Time Finish Time Start Time Units Produced Say youre working on understanding the cycle time for painting the toasters from the earlier example.

So if our customer wants 240 toaster ovens and we have 480 minutes to produce these toaster ovens our takt time is 2 minutes per toaster oven 480240. Daily operating time divided by the product of the desired output and the sum of job times. Therefore the TAKT Time is 20 minutes.

Time Studies The classical approach to time studies was developed by Frederick W. E100 minus station time.

Maximum Allowable Stress An Overview Sciencedirect Topics

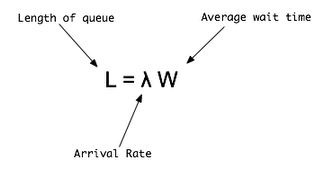

Reduce Cycle Time With Little S Law

What Is The Difference Between Rpo Rto And Mtd Tandem

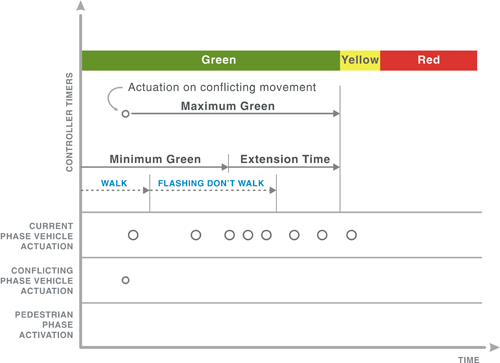

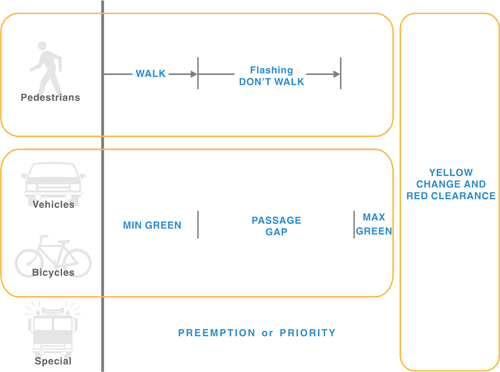

Traffic Signal Timing Manual Chapter 5 Office Of Operations

Calculating Pump Starts And Cycle Time Pumps Systems

Traffic Signal Timing Manual Chapter 6 Office Of Operations

Traffic Signal Timing Manual Chapter 5 Office Of Operations

What Is The Difference Between Rpo Rto And Mtd Tandem

Maximum Allowable Stress An Overview Sciencedirect Topics

Maximum Allowable Concentration An Overview Sciencedirect Topics

Maximum Allowable Stress An Overview Sciencedirect Topics

Consideration Of Demand Rate In Overall Equipment Effetiveness Oee On Equipment With Constant Process Time Puvanasvaran Journal Of Industrial Engineering And Management

Ti Planet Chapter 8 9 Programme Mviewer Gx Creator Lua Nspire

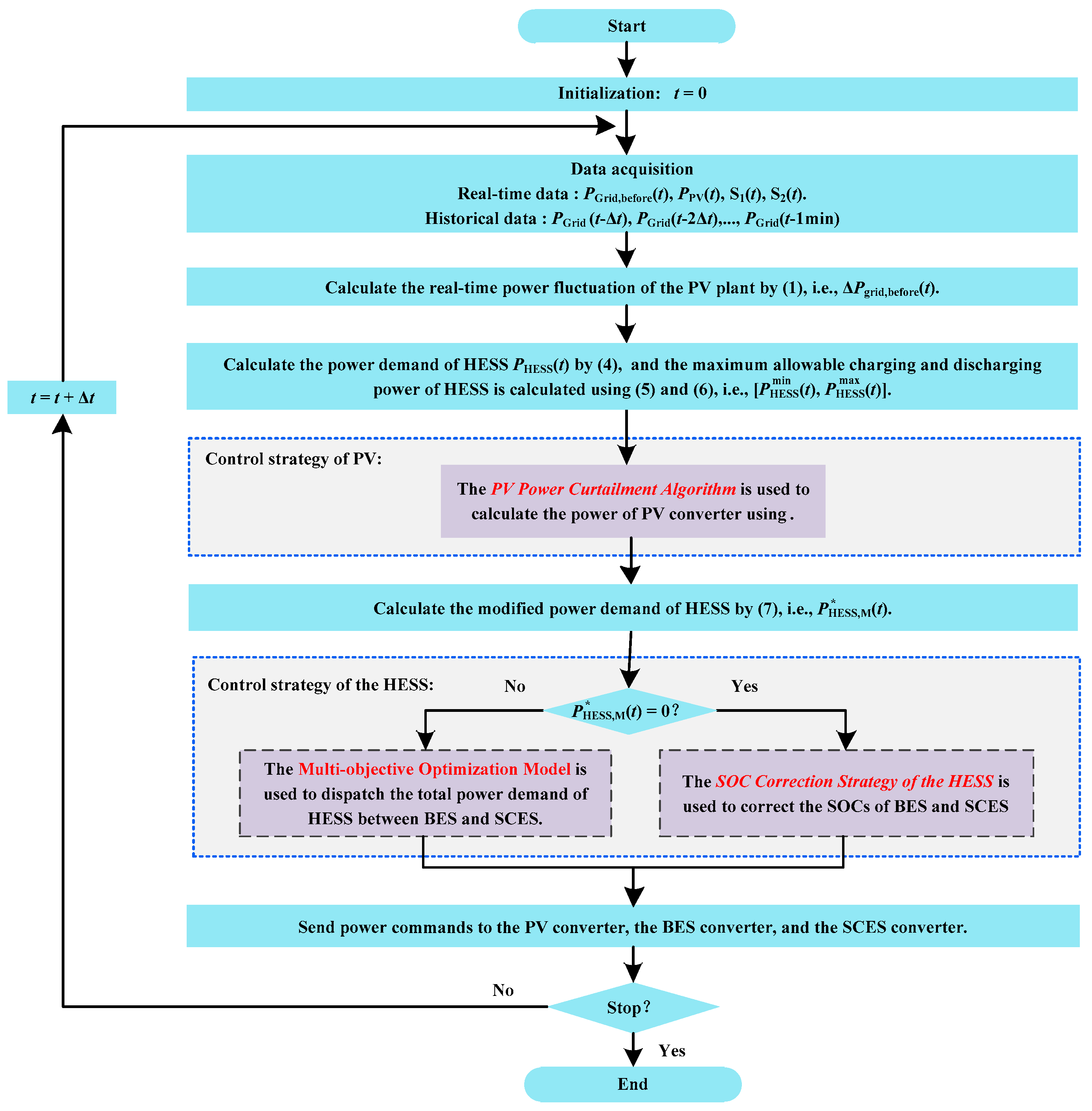

Sustainability Free Full Text Control Strategy Of A Hybrid Energy Storage System To Smooth Photovoltaic Power Fluctuations Considering Photovoltaic Output Power Curtailment Html

Comments

Post a Comment